The higher the demand for rolls and service, the easier the choice – DIRKRA

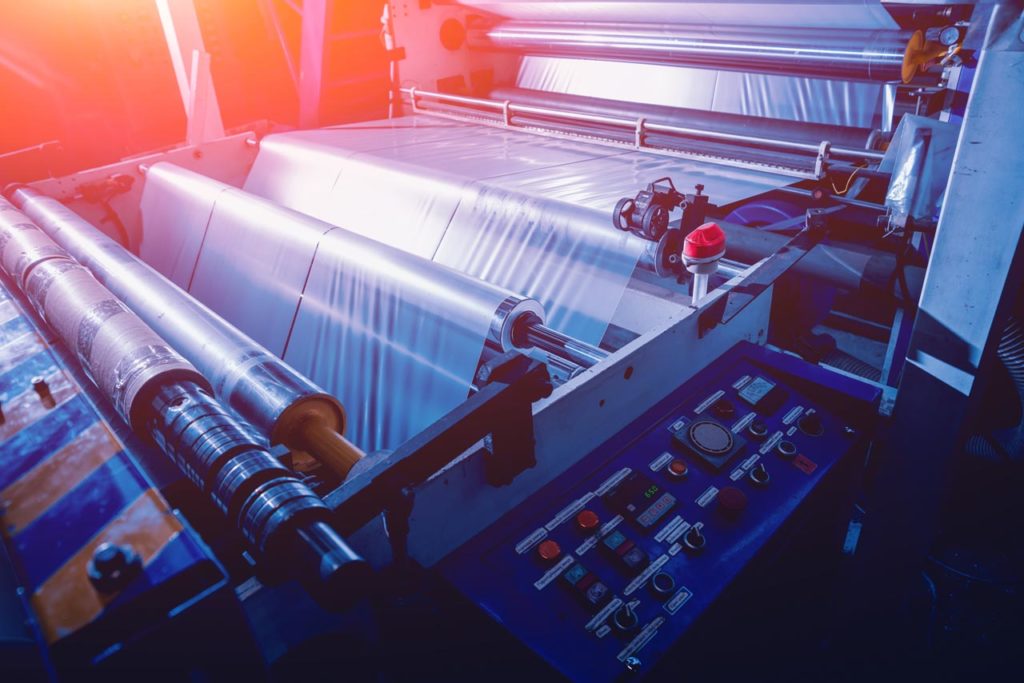

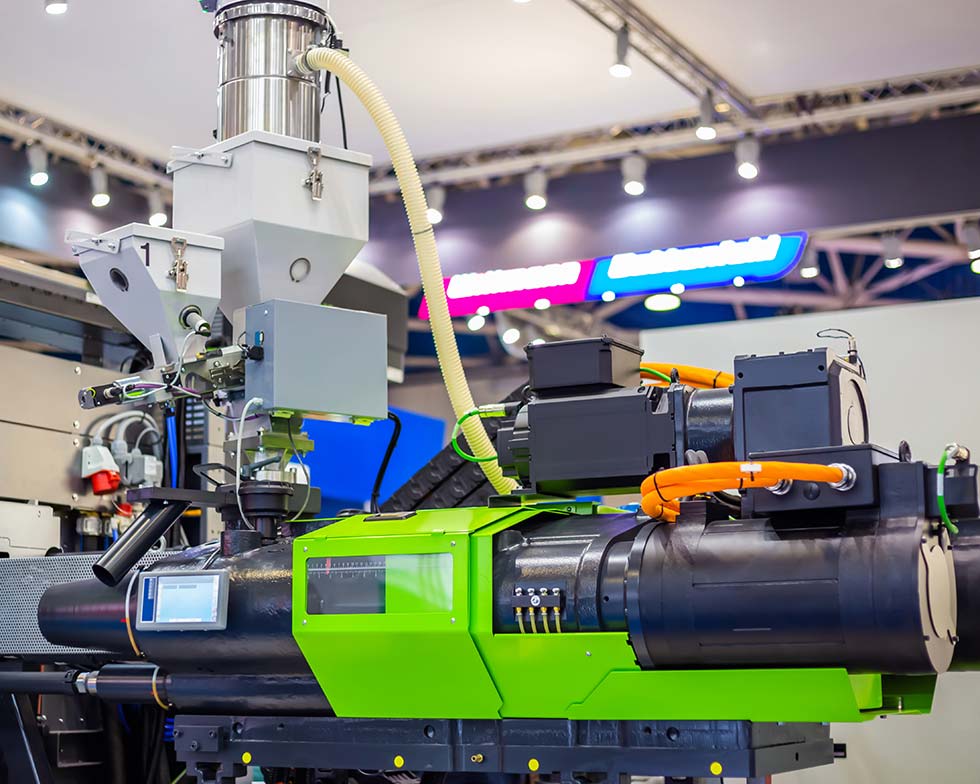

Since our foundation in 1962, we have developed into a modern, globally operating company with a wide range of products and services. In addition to the design, construction and optimisation of rolls for all applications, we also offer contract machining and advice on all matters relating to rolls. The roots of DIRKRA roll manufacturing originate from the copper town of Stolberg. The historical beginnings with the production of pure cold rolls, back-up rolls and work rolls have been extended over the years, to include many other sectors such as steel, non-ferrous metal, paper, foils, food, pharmaceuticals and chemicals. With highly qualified employees and state-of-the-art machinery, we manufacture and process products that meet the highest demands for surface quality as well as shape and dimensional accuracy.

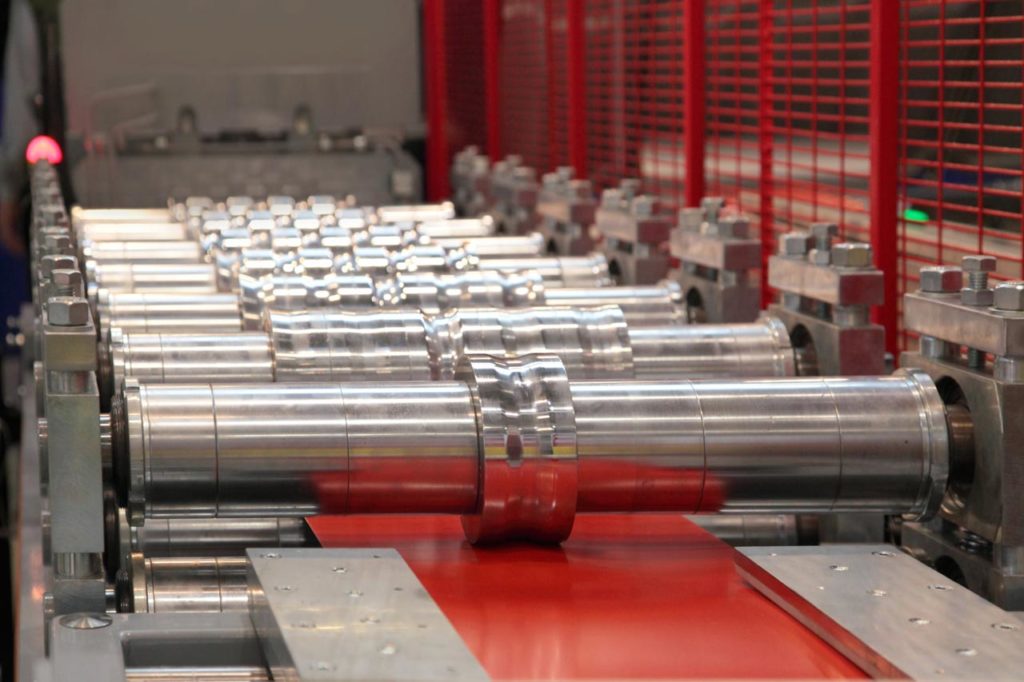

Cold rolls, work roll, back-up rolls

Not only the high flexibility and product quality is important, but also a sustainable and economical operation of your equipment. Choosing rolls from DIRKRA means: You achieve precise strip thicknesses and high surface qualities entirely according to your wishes. High productivity and fast availability as well as low maintenance requirements are the basis for cost-saving production.

Heating and cooling rolls

This type of roll consists of a double-walled construction with a degressive guide spiral. The design forms the basis for precise temperature control with a temperature accuracy of +/- 1° on the bale surface. From cylindrical or crowned to highly polished bale surfaces, everything is possible.

Embossing rolls

Embossing rolls are an established means of producing large quantities of components with structured surfaces at low cost. We distinguish between hot and cold embossing rolls. Both hardened and unhardened embossing rolls are used for this purpose.

Smoothing rolls

Not only our own mechanical engineering department, but also national and international machine and plant manufacturers as well as end customers order our smoothing rolls due to their high quality and reliability. With our technology, the highest accuracies in terms of shape and position tolerance as well as surface quality can be realized.

Special rolls

We have also specialised over decades in the production of special rolls. For example, we manufacture roll bodies made of solid material for the food industry with thousands of 5-axis simultaneously milled bores into which stud pins are inserted. The resulting special roll is an embossing roll used for the production of crispbread, which has a height tolerance of less than ± 0.02mm.

Service centre grinding

For various industrial sectors, we offer the possibility, to precisely grind rolls and knives of different dimensions and applications under program control. Rolls with a diameter of up to 1,500 mm, a total length of 5,500 mm and a mass of 30,000 kg are within our processing range. In addition, industrial knives from scrapping rubber knives to triangular knives or shear blades are ground as well as rubberized ejectors, splash rings or spacer rings.

Particularly interesting for . . .

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more