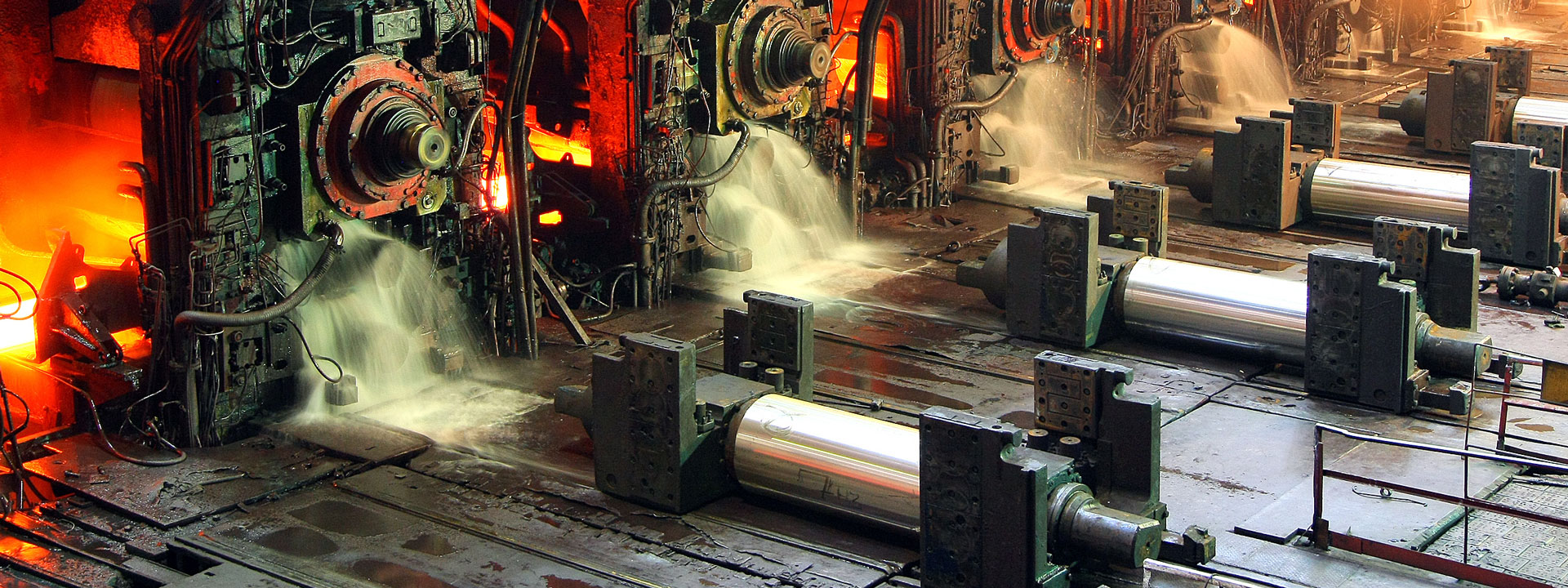

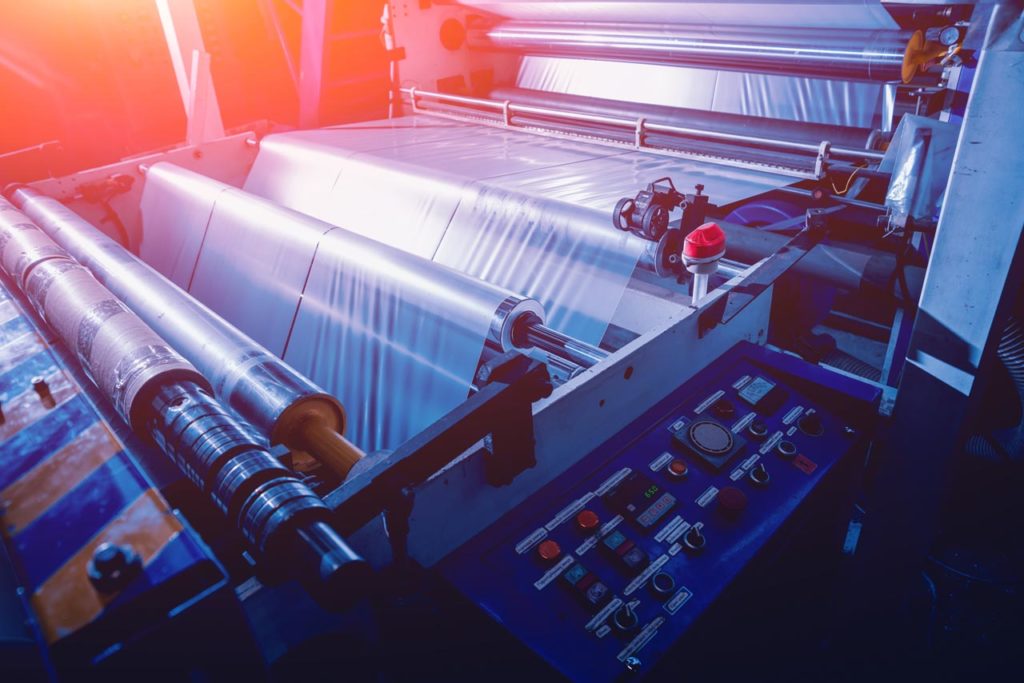

DIRKRA provides machines for the most diverse industrial sectors, which precisely grind rolls and knives of the most varied dimensions and applications under program control. The pick-up and delivery service guarantees low downtimes and fast delivery of your newly ground roll and knife parts. Our range of services extends from grinding your back-up rolls over cold and hot rolls to rubber and embossing rolls. Rolls in dimensions up to 1,500 mm diameter, a total length of 5,500 mm and a mass of 30,000 kg are in our processing spectrum. In addition, industrial knives from scrapping rubber knives to triangular knives or shear knives are ground as well as rubberized ejectors, splash rings, inner rings, spacer rings, and many more. We offer all common types of grinding from mirror polished to crowned or hollow to CVC grinding.

CNC rollgrinding

DIRKRA provides machines for the most diverse industrial sectors, which precisely grind rolls and knives of the most varied dimensions and applications under program control. The pick-up and delivery service guarantees low downtimes and fast delivery of your newly ground roll and knife parts. Our range of services extends from the grinding of your back-up rolls to cold and hot rolls, rubber rolls and embossing rolls. Rolls in dimensions up to 1,500 mm diameter, a total length of 5,500 mm and a mass of 30,000 kg are in our processing spectrum. In addition, industrial knives ranging from scrapping rubber knives to triangular knives or shear blades are ground, as are rubberized ejectors, splash rings, inner rings, spacer rings, and much more. DIRKRA offers all common types of grinding from mirror polished to crowned or hollow to CVC grinding.

CNC cylindrical grinding

With our cylindrical grinding machines we grind workpieces, rolls and knives with a weight of up to 350 kg, a grinding diameter of max. 500 mm and a point width of 1,500 mm. Take a look at our machinery. The Schaudt cylindrical grinding machine UR 1500 offers the best dimensioning for intermediate sizes and less heavy workpieces. With a max. workpiece weight of up to 300 kg, it preferably grinds rolls and knives that require a grinding diameter of max. 500 mm and a point width of up to 1,500 mm. Our TOS-HOSTIVAR cylindrical grinding machine type BUB 500/1500 is predestined for workpieces with a weight of up to 350 kg, a required grinding diameter of 500 mm and a point width of 1,500 mm.

CNC helical milling

During hot rolling in the non-ferrous metal industry, an oxide layer (scale) is formed on the surface of the strips. This layer must be removed before further processing of the material. Helix cutters are used for this task, which simultaneously mill off the strip on the upper and lower side by approx. 0.6 mm each. The helix cutters used are high-precision tools and therefore also place extraordinary demands on regrinding. As a special highlight, our grinding centre has specialised in the regrinding of Helix cutters. The extremely hard cutting tools require a high degree of feeling and precision during machining. Thanks to many years of experience and excellent machinery, DIRKRA has achieved an outstanding market position in this specialist field.

Particularly interesting for . . .

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

Your contact partners

Grinding Centre

Grinding Centre