The requirements for the technical cleanliness of workpieces have increased rapidly in recent years, which is why users of industrial cleaning technology are faced with new challenges. An optimal process flow can only be guaranteed, with regard to technical feasibility and taking into account the cost structure, if the individual machining steps and cleaning processes are precisely planned and coordinated with each other. Through synergies from decades of experience in special machine construction and industrial cleaning technology, we implement highly efficient and innovative special solutions.

Single-chamber cleaning system

Industrially manufactured individual workpieces as well as bulk materials can be efficiently cleaned in our single-chamber cleaning systems, both manually and through automated interlinking. The system is characterized by a very compact design and combines the cleaning steps of degreasing, cleaning and drying.

Water treatment I Filtration technology

To increase sustainability and reduce operating costs, we develop innovative concepts for the separation of solid components from fluid substances. Depending on the respective contamination, our service portfolio ranges from coarse pre-filtration to ultra-fine treatment.

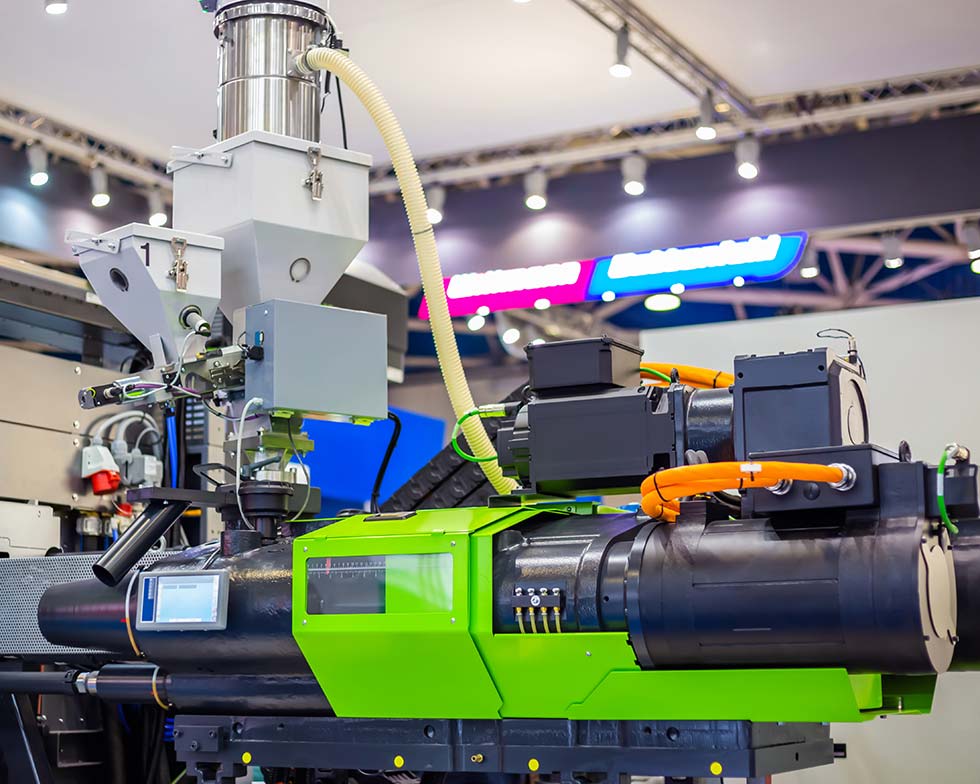

Dry cleaning system

Due to the cost-optimized high-pressure dry-cleaning process, this plant design is ideally suited for the rapidly growing e-mobility market. To increase the technical availability of upstream or downstream equipment, we use it in the intermediate cleaning of complex production lines.

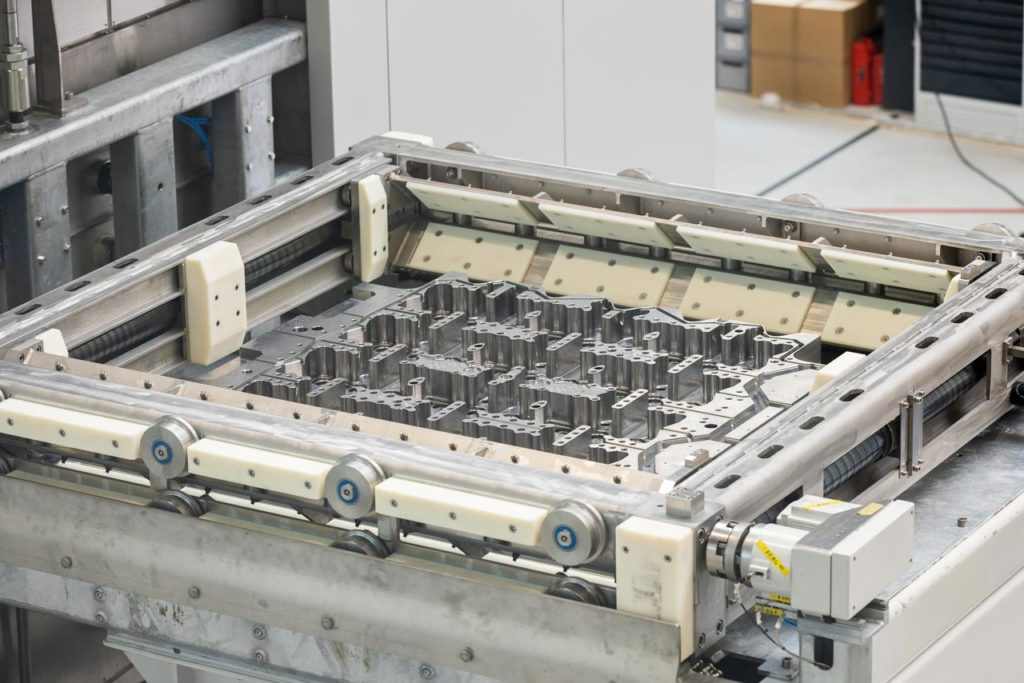

Continuous cleaning system

Due to the conceptual solution of a multi-chamber system, specific and individual cleaning and drying steps are carried out in the individual areas. The continuous cleaning systems are designed for automated, continuous or intermittent operation for integration into production lines.

Conversion I Upgrade I Retrofit

With our experienced service team in the field of cleaning technology, we offer you product-specific conversions, as well as individual modernization measures for your existing plants. With your existing Beyss system, you will benefit from an extended service life and optimized performance at the same time. In addition, we are also happy to develop specific solution concepts for third-party plants.

Spare and wear parts

In order to ensure the full performance and optimum availability of your existing plant, we manufacture spare and wear parts according to your drawings, samples or measurements. In addition, we supply you with original spare parts for your BEYSS systems of all types, to guarantee the usual quality.

Particularly interesting for . . .

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

learn more

Your contact persons

Cleaning technology

Cleaning technology